Contents

Ever wondered what powers all the electrical components in your car with the engine running? Most people guess it’s the battery, but guess wrong. Your vehicle’s alternator provides the needed current for things like the air-conditioning, lights, windows, and various electrical and electronic parts, such as the ECU, ABS or cruise control, and other related systems that we now take for granted. And while the alternator plays a crucial role, without the battery, starter motor, the kilometres of wiring in each car, and basic safety and convenience tech like fuses, relays, and sensors, all the hard effort it puts towards producing electricity goes to waste. Let’s take a detailed look at what the alternator does, how it’s built, and the different types and common issues with faulty alternators. The data here will provide you with the right info when you need a replacement.

What are Car Alternators?

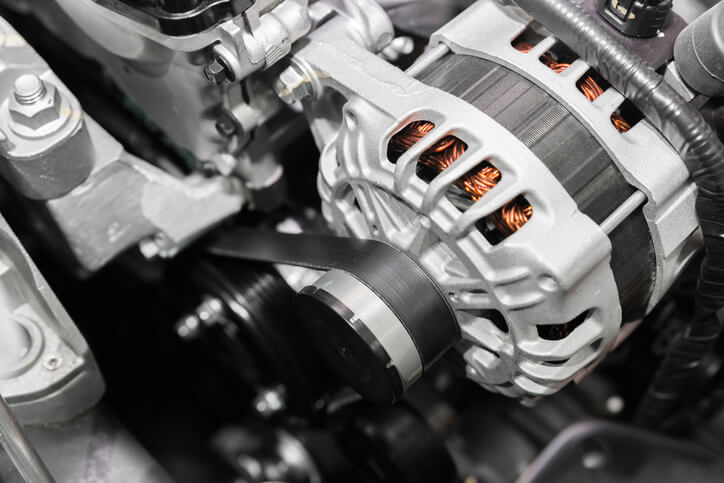

An alternator is the car part that produces electricity while the engine is spinning. It’s bolted onto the engine block and has a system of belts or pulleys connecting it to the crankshaft. This is what provides the mechanical energy to spin. In short, a car alternator converts mechanical energy into electricity, and this is used to replenish the battery and power various vehicle systems and parts that rely on electricity. But this power supply is only available when the car is running. The initial power supply to get the engine going and turn the crank is from the battery and starter motor. This takes a matter of moments, and from there on, the alternator takes its place.

Anatomy of an Alternator and How it Works

In order to understand how automotive alternators work, we must first familiarise ourselves with the different parts. These all perform vital roles.

- Housing – This is what encases all the internal components. It’s often made of aluminium to reduce weight and allow for good corrosion resistance. Housings are also vented to dissipate heat from the spinning parts inside.

- Stator – This is the circular, non-moving part in the alternator, consisting of copper wire coils wound around an iron or steel core. The role of the coils is to induce a magnetic field in order to produce an electric current, by way of electromagnetism. For this to happen though there is the need for a moving part, one driven by belts and pulleys.

- Rotor – This is the spinning electromagnet and provides the magnetic field as it spins around the stator. It does this with the help of the crank and pulleys and belts that connect them. Inside the rotor you’ll find carbon brushes that convey current to the magnet core and coils surrounding it, copper slip rings attached to the coil ends to pass on current and slip ring end bearings that support the weight of the rotor as it turns.

- Rectifier – The assembly produces alternating current (AC) and the rectifier, consisting of several diodes, converts this to usable direct current (DC). It is this type of current that charges the battery.

- Voltage Regulator – This is what controls the amount of current reaching the battery. It also protects the battery and connected circuits from overloads.

Other alternators and related parts include the pulley, the alternator belt, alternator connections and leads, engine mounting brackets and belt tensioners.

The process of producing electricity goes like this: the engine starts and turns the crank. This spins the belts and pulleys and in turn, is what gets the rotor moving. The coil windings in the rotor are fed direct current from the battery and produce magnetic flux. This induces an electromagnetic field in the stator windings. The generated AC current is then sent through the rectifier and converted to DC, then flows onto the voltage regulator and through the alternator leads to recharge the battery and power any connected (or switched on) circuits.

Signs of a Bad Alternator

Since so many vehicle systems rely on the car alternator for power, there will be more than a few signs that the alternator is failing or will soon call it quits. The most obvious is the battery sign on the dash and this indicates either a drop or surge in voltage. While not exactly pinpointing that the alternator is at fault (might be a dead battery), drivers will definitely have trouble starting the car in the first place, and when it does stall happens soon after. The alternator provides current for basic engine systems like the fuelling, so no current reaching these parts means the engine also suffers.

Another related sign is dimming or flicking headlights, usually slow operation of electric windows, stuck wipers, radios that don’t work, and more. These parts aren’t getting enough voltage to function as they should. Also, you may hear whining or squealing noises under the bonnet, indicating problems with the pulleys, tensioner or belts, or from worn bushes and bearings. This can also be accompanied by the smell of burning rubber. When the issues persist for longer periods, a failing alternator will also lose the ability to charge the battery. Eventually, you might need to replace both.

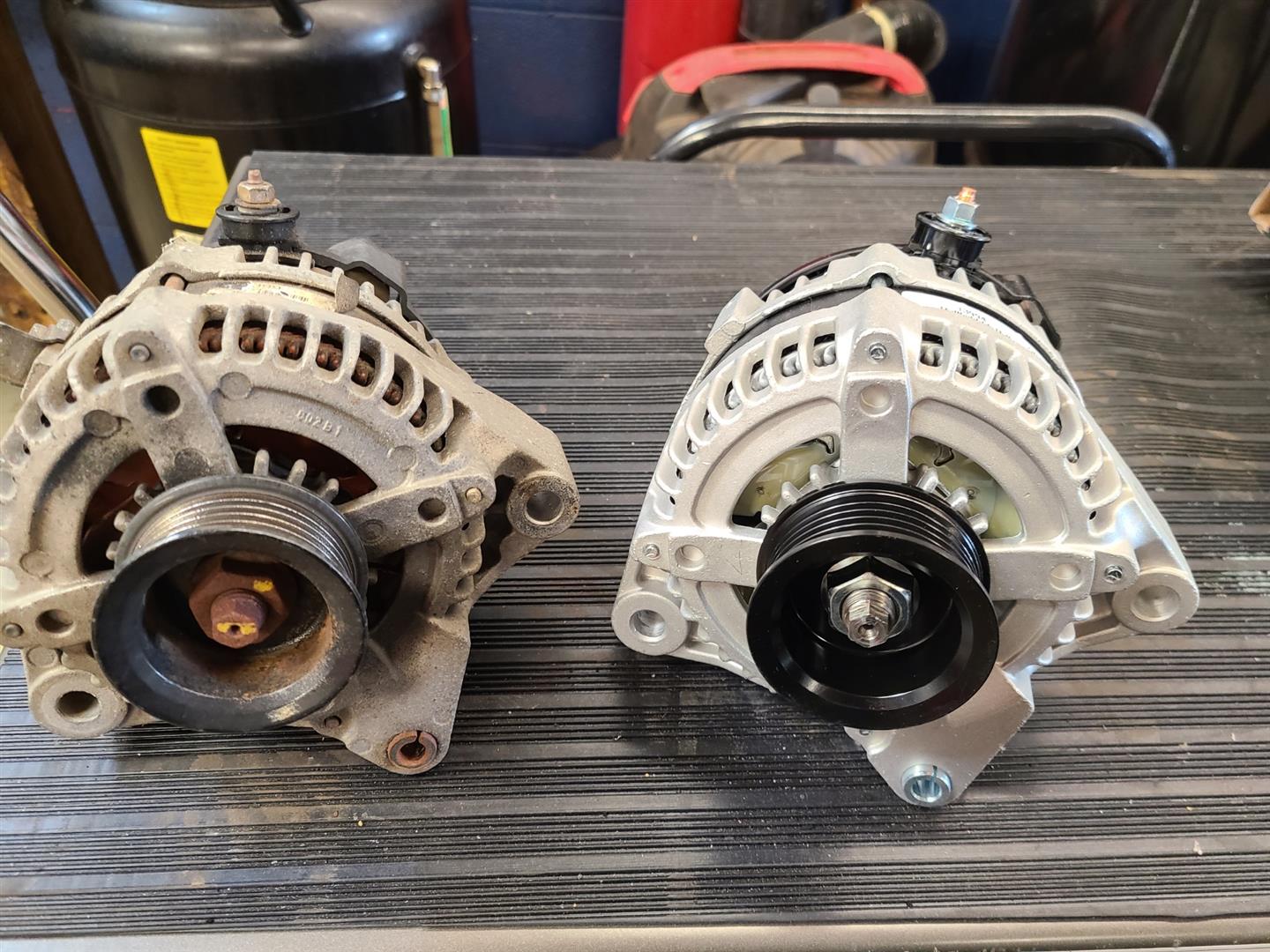

Causes for the issues often lead to loose pulley belts, faulty diodes, issues with the regulator circuitry, damaged or frayed coils, loose connections, jammed tensioners, and more. While rebuilding an alternator is a possibility, this electrical system component is relatively cheap to buy. Go by part number to ensure that you get what’s right for your car