Compressed gas cylinders are classified as dangerous goods, requiring careful handling only by trained personnel. Whether you’re a staff member or contractor, knowing the right techniques helps maintain safety on the job. Read on to take a closer look at how this gear is commonly used across workplaces and explore the health and safety risks involved. More importantly, you’ll learn practical ways to manage those risks effectively by adopting safe handling practices, helping you protect yourself and your team.

Industrial Equipment

A Step-by-Step Guide to Choosing the Right Workbench for Your Needs

The right workbench can help you create a space that supports your craft, enhances your workflow, and stands up to the demands of your projects. It can also improve your comfort, streamline your workflow, help you organise your tools, and even make your workspace safer. I’ll take you through the steps to identify the four key features you should look for when shopping for the perfect bench, so you can feel confident you’re investing in one.

Portability

It’s essential to move your setup with ease when you’re constantly shifting between tasks or spaces. You can adapt to your environment instead of being stuck working around it with the help of a lightweight mobile workbench. Whether you’re tight on space or need to clear the area once the job’s done, with this setup you can fold up, roll away, or tuck it into a corner.

You want a setup that’s light enough to move without a struggle but still solid enough to hold up under pressure. Look for features like built-in wheels or collapsible frames if you know you’ll need that kind of flexibility. And if you’re doing jobs on the go, like for mobile repairs or at different job sites, something easy to transport is going to save you a lot of hassle.

While we’re on the topic of portability, it also matters how much weight your setup can handle. You don’t want to be halfway through something only to realise your surface isn’t built to support the load. Whether you’re working on small repairs or handling heavy-duty machinery, you should know the capacity your station was built to take. Always think about the tools and materials you use most often.

For example, if you’re welding, a heavy-duty workbench is a must. This craft brings heat, weight, and a lot of sparks, so you need a solid setup that won’t budge or get damaged. A sturdy, heat-resistant surface will make your work safer, cleaner, and way more reliable. There’s a balance to be found between mobility and strength, and getting it right means you’ll have a setup that works hard and lasts longer, too.

On the other hand, for woodworking projects where you’re cutting wood with a circular saw, you’ll want a medium-duty mobile workbench that won’t wobble when you’re working. It doesn’t have to be super industrial, but it should be stable, with a solid top and enough space to lay out your materials comfortably. If you’re cutting full sheets or working on bigger builds, it’s a plus to have a setup with clamping options and room to manoeuvre.

Durability

When you’re setting up your workspace, one of the most important things to think about is how tough your setup is. Durability matters, especially if your projects are heavier or involve bulky tools. A strong, well-built surface will make sure your space stays safe, reliable, and ready for anything you’re working on.

Whether you’re drilling, hammering, sawing, or stacking equipment, look for workbenches that can take the pressure. The last thing you want is something that shifts, wobbles, or shows signs of wear too soon. And when you’re dealing with powerful tools that create vibration or impact, durability becomes even more important for safety. Here are a few reasons why you should look for a durable workspace setup:

- Takes on heavy-duty tasks without cracking or becoming unstable;

- Helps prevent accidents by staying solid and steady;

- Withstands tool vibration and weight without wearing down;

- Resists everyday wear and tear, dents, scratches, and spills;

- Lasts longer, so it’s a better investment for the long haul.

Storage Space

When you have a lot of tools, materials, and equipment to work with, having storage built into your tool workbench can make a difference. These compartments keep everything organised so you can grab what you need without wasting time hunting through piles of tools or clutter. A well-designed work area with integrated storage helps reduce mess, keeps your space tidy, and improves safety and productivity.

Make sure the storage doesn’t eat into the surface space you need for bigger projects. You want to have enough room without feeling cramped, while still having everything in reach. Think of clever storage solutions like drawers, shelves, or even pegboards on the sides for easy tool access. You might also want to consider extra space underneath for the larger gear, so it’s always available but doesn’t get in your way.

Surface Material

What’s the best material for a workbench top? When choosing the right workspace, the surface material plays a huge role in the quality of your project and your comfort while you’re working. The surface you choose should be tailored to the type of projects you’ll be doing most often.

For example, some materials can absorb vibrations better, while others might be more prone to damage if you’re working with heavy tools. You should also think whether the material could end up damaging your tools or workpieces. Here’s a quick look at some common surface materials and what they’re good for:

- Wood: A traditional favourite, especially for woodworking. It’s easy on your tools and gives you a smooth, familiar working surface;

- Steel: This is your go-to for heavy-duty tasks, industrial jobs, and metalworking. It’s durable but can damage softer materials like wood if you’re not careful;

- MDF or Laminate: These are great budget-friendly options. They provide a flat, smooth surface that’s perfect for an art studio. This kind of surface is ideal for detailed artwork, drawing, painting, or crafting;

- Rubber or Plastic: These materials are perfect for delicate work. They’re non-slip and durable, which prevents damage to fragile projects or tools.

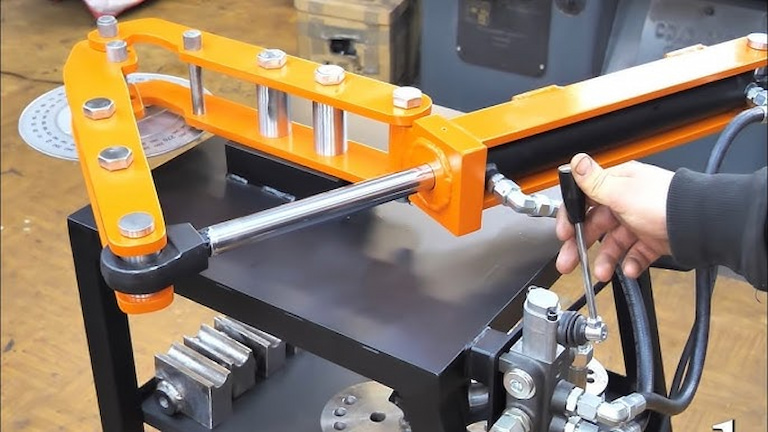

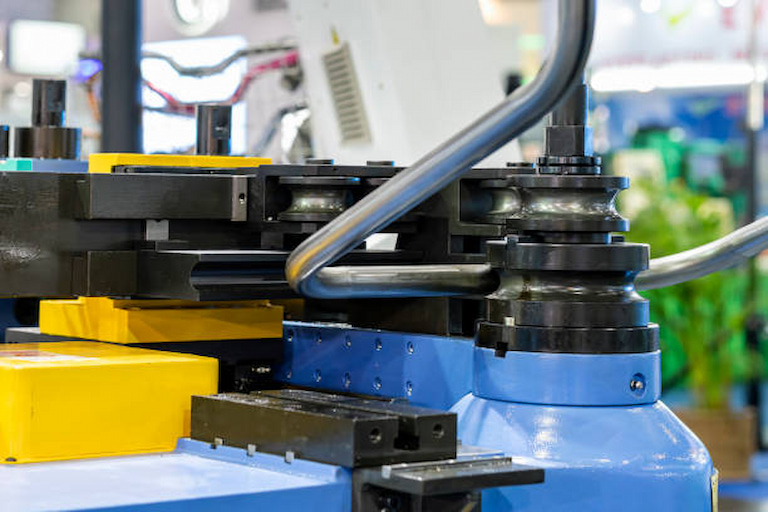

Hydraulic Pipe Benders: A Practical Guide to Precision Pipe Bending

In the world of metalwork, a hydraulic pipe bender is a game-changer for anyone who needs to bend pipes accurately and efficiently. Whether you’re in the business of creating custom piping for automotive work, construction, or industrial use, hydraulic pipe benders provide a reliable and powerful solution for shaping pipes with precision. Unlike manual methods, hydraulic pipe benders take the strain out of bending and deliver consistent, repeatable results, even on tougher materials.

What is a Hydraulic Pipe Bender?

A hydraulic pipe bender is a machine used to bend pipes and tubing without causing damage to the material. These benders use hydraulic pressure to exert a controlled force on the pipe, allowing for smooth and accurate bends with minimal distortion. Designed to handle various metals like steel, stainless steel, and aluminium, hydraulic benders are essential for professionals who need reliable and accurate bends in their work.

The beauty of hydraulic pipe benders lies in their versatility. They can produce bends in different radii and angles, making them suitable for everything from simple bends to complex, multi-angle bends required in custom metalwork projects. With a hydraulic bender, achieving the right curve in heavy-duty pipes becomes manageable, saving both time and effort.

Why Choose a Hydraulic Pipe Bender?

Hydraulic pipe benders make metalwork easier, more accurate, and efficient. Here’s a closer look at why they’re so beneficial:

Precision and Control

Hydraulic pipe benders offer precise control over bends, ensuring each angle is accurate. In jobs like construction and automotive work, where exact angles are critical, this accuracy helps avoid errors that could compromise safety or functionality.

Effortless Operation

Hydraulic systems do the heavy lifting, so you don’t have to. By using controlled pressure, the machine takes on the physical strain of bending, making it easier on operators, especially for longer or more complex jobs.

Versatility Across Metals and Pipe Sizes

These benders handle a variety of metals, from mild steel to stainless steel and softer metals like copper. They’re also adaptable to different pipe sizes, meaning one tool can handle a wide range of tasks without requiring additional equipment.

Consistency and Reduced Material Waste

Hydraulic pipe benders are designed to deliver uniform bends every time, cutting down on material waste from mistakes and distortions. This consistency saves money on materials and helps create a clean, professional finish for any project.

Key Features of Hydraulic Pipe Benders

When choosing a hydraulic pipe bender, a few core features will determine its suitability for your needs:

Bending Capacity

The bending capacity is the maximum diameter and thickness the machine can bend. If you’re working with larger pipes, be sure to choose a model with sufficient capacity. For lighter jobs, a smaller bender may be more portable and easier to handle.

Ease of Operation

Some benders have simple lever controls, while others come with digital settings for more advanced precision. Consider your comfort level and the requirements of your projects when choosing the right type of control.

Portability and Space Requirements

Hydraulic pipe benders come in portable and fixed models. Portable benders are great for on-site jobs, offering flexibility, while fixed units are more robust and suitable for workshop environments. Assess your workspace to decide which suits you best.

Quality and Durability

Investing in a well-built, durable bender will pay off in the long run. Look for solid construction, high-grade hydraulics, and sturdy dies. Quality machines not only perform better but are safer to use under high pressure.

Popular Uses for Hydraulic Pipe Benders

Hydraulic pipe benders are commonly used across different fields for a variety of applications:

Automotive Fabrication

Hydraulic benders are ideal for custom automotive work, such as bending pipes for exhausts or roll cages. They allow precise bends needed to fit vehicle parts correctly and safely, meeting both performance and aesthetic standards.

Construction and Infrastructure Projects

In construction, hydraulic pipe benders make installing pipes for water, gas, or electrical conduits simpler and more accurate. Their precision reduces the likelihood of leaks and other issues, which is essential for long-term durability.

Industrial Manufacturing

For industrial applications, these benders handle large-diameter pipes and structural elements with ease. They provide reliable bending for heavy-duty materials, making them essential in manufacturing environments where safety and accuracy are critical.

Metal Art and Custom Fabrication

In custom metalwork and art, hydraulic pipe benders offer the control needed to create unique shapes and complex curves. Their versatility makes them a favourite tool among metal fabricators and artists alike.

Tips for Using a Hydraulic Pipe Bender

For safe and effective use, follow these tips to make the most of your hydraulic pipe bender:

Choose the Right Die

Using the correct die size helps prevent pipe crimping and distortion. Check the manufacturer’s guidelines for die selection to match the pipe’s diameter and material for a smooth bend.

Monitor Hydraulic Pressure

Maintaining the right pressure is key to getting accurate results and keeping the machine safe. Too much pressure can damage both the pipe and the machine, while too little may result in poor bends.

Secure the Pipe Properly

Make sure the pipe is clamped securely to avoid slipping or misalignment. Most benders have adjustable clamps or vices that keep the pipe in place during the bending process.

Regular Equipment Maintenance

Regularly inspecting hoses, dies, and hydraulic components extends the life of the bender and ensures it remains safe to use. Maintenance is essential to keep the tool performing at its best, especially under heavy usage.

Final Thoughts

A hydraulic pipe bender is an excellent investment for professionals in metal fabrication, construction, and automotive industries. Its precision, power, and ease of use make it invaluable for anyone needing consistent and accurate pipe bending. With the right hydraulic pipe bender, you’ll be able to tackle complex projects with confidence, delivering high-quality results that meet industry standards. By considering features like capacity, durability, and portability, you’ll find a machine that fits your needs and enhances your productivity on every project.

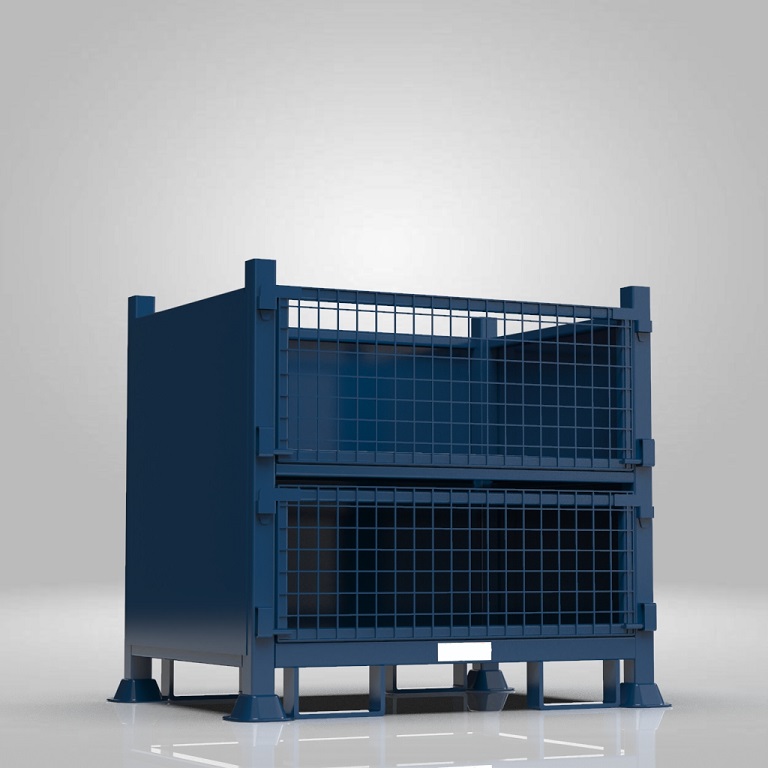

Industrial Stillages and Cages: The Ultimate Solution for Efficient Inventory Management

In the busy world of commerce, one of the most important things is having a warehouse, and not just any warehouse, but a well-organised and tidy one. By having this space, you will have smoother operations, timely deliveries and many other advantages. To ensure that your warehouse is organised, you’re going to need to invest in items that will provide you with the space and those items are the much-needed stillage and cages. So, let’s look at the types and the benefits that they offer.

Protective Gear 101: Steps to Choosing the Ideal Welding Lenses

Every job has its risks, but some require more protection than others. Take welding as an example – given that it’s to do with joining metals together, like aluminium parts, it’s a process that relies on a lot of use of heat and pressure. Since there are arcs that result from this joining, doing everything you can to protect the eyes is considered a necessary safety measure.

What happens if you don’t wear glasses when welding? Let’s just say eye injuries are guaranteed. As to what kind and how severe, it depends on the level of exposure. The radiant energy that’s the result of the welding causes a condition known as welders’ eye or welders’ flash, which is the injury to the surface, the conjunctiva.

Not to mention, there’s flying metal debris you need to beware too. Besides pain, swelling, and blurry vision, temporary blindness, more serious UV radiation (as bright as the sun) and exposure to metal dust can also lead to permanent blindness. Why go through this risk, when you can get the protection you need from a hard-coated and anti-fog welding lens created to shield your eyes?

The Comprehensive Guide to Self-Tapping Screws for Metal

In the vast universe of fasteners, self-tapping screws for metal stand out as a cornerstone, essential for both industrial applications and everyday DIY projects. These ingenious little components have the power to streamline assembly processes, ensuring strong and durable connections in metalwork. This article delves into the essence of self-tapping screws, and their application spectrum, and offers practical advice on selecting the right variant for your needs. Additionally, it navigates the economical aspect of purchasing these screws in bulk from online wholesalers, a strategy that promises substantial savings.

Efficient Tool Organisation with Storage Boxes: A Step-by-Step Guide

Have you ever found yourself rummaging through a messy toolbox or cluttered workspace, struggling to find the right tool for the job? Well, it’s time to say goodbye to those frustrating moments! With the right storage solutions and proper organisational methods, all those problems can be a thing of the past. From stepping into the realm of workspace organisation to mastering the art of using toolboxes effectively, this guide is your roadmap to a more streamlined and productive workspace.

Steps to Selecting the Right Floor Scrubber for Your Establishment

Floor scrubbers help your staff clean the floors quickly and efficiently. When you’re looking for the right one for your establishment, you need to make sure that it’s reliable, efficient, and aligned with your unique needs. There are plenty of options that can either elevate your cleaning game or leave you grappling with frustration. So, let’s go over the key factors to guide you through this pivotal decision-making process.

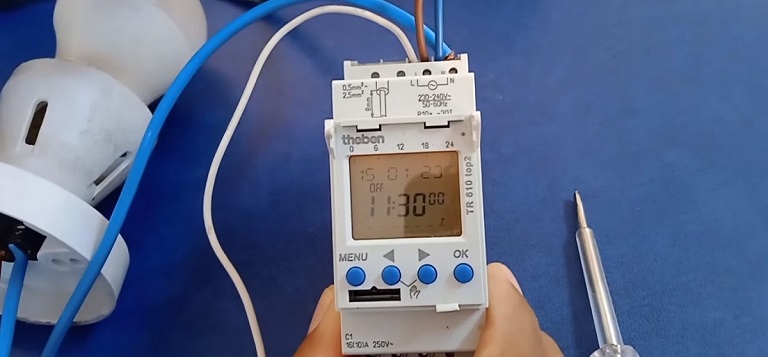

Mastering Precision: Navigating the Realm of Digital Time Switches in Industrial Applications

In the intricate tapestry of industrial operations, the precision of time management is a silent force that wields significant influence. At the heart of this orchestration are digital time switches—unsung heroes that play a pivotal role in optimizing processes, enhancing efficiency, and fostering resource conservation.

This comprehensive exploration delves into the multifaceted uses of digital time switches in industrial settings, their impact on diverse applications, and the essential considerations in choosing the right digital time switch for specific requirements.

Cage Trolleys: Versatile Solutions for Material Handling

In the world of material handling systems, cage trolleys are an essential component in various industries, providing a convenient and efficient means of transporting goods within a facility. These trolleys are designed with a cage-like structure to secure and move items, making them indispensable tools in warehouses, manufacturing plants, and distribution centres. Now let’s explore the features, uses, and benefits of cage trolleys, shedding light on their importance in streamlining logistics and enhancing operational efficiency.

Unlocking Workspace Potential: The Power of Richmond Workbench Casters

Ask any tradie, chippie, or even hobbyist if they’re completely happy with their workspace, and they’ll probably say no. And not surprisingly, the one resource that they’re all likely to profess that they’re sorely lacking is space.

Steps to Storing and Maintaining Your Work Tools

Organising and storing your tools on the construction site or inside your workshop can go a long way in preventing loss and damage. Here are some tips on how to organise your tools.

The organisation of tools is one of the most important aspects of any trade. Having a systematic way of storing them will help prevent loss, theft and accidental damage. It also makes it easier for an individual to find what he needs quickly when working on a project. Organising your tools can be done indoors or outdoors depending on the amount of space available and the number of tools involved.

Workplace Safety: Pro Choice Safety Gear Guide

Safe Work Australia defines personal protective equipment (PPE) as anything an employee uses or wears to keep safe and healthy in the workplace. This is to be provided by the person conducting a business or undertaking (PCBU), in addition to the appropriate training and instruction to use it.

Tool Box Guide: Where Practicality Meets Safety

Whether you’re a homeowner, a devoted DIY-er, or a tradie, you’ll want the right tools for the job. And you’ll want those tools stored in a safe location, organised, and easily accessible. There are different types of storage solutions for tools and parts that you use at the worksite. They’ll differ by the type and size of tools, as well as the amount they can carry.

No Loading Dock? No Problem: Load and Unload Your Large Items with Walk Ramps

For operations that don’t have a designated loading dock, walk ramps are a great solution. They enable the loading and unloading of items safely and efficiently when using standard hand trucks, dollies and two-wheeled handcarts. This type of ramp can help roll your moving equipment into your trailer, box truck, cube van or else.

Steps to Choosing the Right Starter Bars

Many construction projects involve the production of concrete walls, slabs, masonry walls, and so on. For that reason, these walls and slabs must be structurally strong enough to meet safety and project requirements. This is commonly done with steel reinforcement in both commercial and domestic projects, and there are many different types of steel reinforcement products for this purpose. One of the most popular types of steel reinforcement products is starter bars. Reinforcement starter bars can be used in a range of applications, depending on how they’re used and their properties. Here’s what you need to know when shopping.